INA (Schaeffler) covers rolling bearings, plain bearings and linear technology. Here you’ll find a clear overview of series, cage options, seals and preload classes, plus practical criteria to balance load capacity, speed and service life in your design.

What you will find in the catalogs

- Ball bearings – deep groove, angular contact, self-aligning.

- Roller bearings – cylindrical, tapered, spherical; open and sealed.

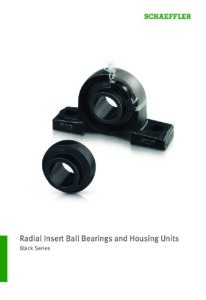

- Units & housings – plummer blocks, flanged and take-up units.

- Special executions – high-temperature, corrosion-resistant, low-noise.

- Dimension tables – bore, OD, width, load ratings and limiting speeds.

How to select the right product

- Operating conditions: load, speed, duty cycle and ambient temperature.

- Environment: moisture, dust, chemicals, food-grade or washdown needs.

- Fit & clearance: tolerance class, internal clearance, preload.

- Dimensions: space constraints, shafts, bores and mounting interfaces.

- Life & reliability: target service life, lubrication strategy and maintenance plan.

- Compliance: applicable standards, certifications and industry requirements.

Key advantages

- Reliable performance under demanding industrial duty cycles.

- Interchangeable dimensions compliant with international standards.

- Material and coating options for corrosion, wear and noise reduction.

- Clear documentation to speed up maintenance and procurement.

Typical industries

Packaging & bottling, material handling, machine tools, agricultural equipment, steel & cement plants, mining & aggregates, automotive production lines and renewable energy systems.

Need a cross-reference?

Send the current code (OEM or competitor), key dimensions and operating data. We will propose the closest INA equivalent and any matching accessories.