In industrial mechanics, bearings are crucial for ensuring smooth and efficient machine operation. However, even the highest-quality bearing can fail prematurely if installed within a misaligned system. Among the main causes of early bearing wear, shaft misalignment is one of the most common and destructive — and often one of the most underestimated.

Even a slight misalignment between shafts can cause abnormal loads, vibrations, and overheating, leading to premature bearing failure. Understanding how and why this happens is key to optimizing machinery performance and extending operational life.

What Shaft Alignment Means

Shaft alignment refers to the geometric relationship between two or more coupled rotating shafts.

When properly aligned, the shaft centerlines are collinear, allowing torque and motion to be transmitted smoothly and evenly.

Misalignment, on the other hand, introduces unwanted radial and axial forces that increase stress on bearings, couplings, and seals.

There are two main types of misalignment:

-

Parallel (offset) misalignment: the shafts are parallel but not in line.

-

Angular misalignment: the shafts form an angle between them, creating an uneven load distribution.

In most industrial machines, a combination of both types is present to varying degrees, which amplifies mechanical stress.

Causes of Shaft Misalignment

-

Improper installation: inaccurate positioning of supports or housings during assembly.

-

Structural deformation: shifts caused by vibration, load cycles, or foundation settling.

-

Component wear: loosened or damaged bearings causing shaft movement.

-

Thermal expansion: different materials expand unevenly at high temperatures.

-

Maintenance errors: replacing bearings or couplings without checking geometry.

How Misalignment Affects Bearings

Uneven Load Distribution

Misalignment causes bearings to carry loads unevenly, increasing localized pressure on rolling elements and raceways. This accelerates fatigue and leads to early pitting or cracking.

Excessive Vibration and Noise

Vibrations increase exponentially with misalignment. They shorten component life, degrade lubricant films, and cause discomfort or instability in the machinery.

Heat Generation and Lubrication Failure

Friction rises as alignment worsens, resulting in higher operating temperatures and faster lubricant degradation.

Premature Failure

Continuous misalignment leads to excessive wear, lubricant breakdown, and eventually bearing seizure or catastrophic failure.

Detecting Shaft Misalignment

Common signs include:

-

high vibration levels,

-

irregular bearing temperatures,

-

noise or metallic sounds,

-

lubricant discoloration,

-

uneven bearing wear,

-

frequent bearing replacements.

Correct Alignment Techniques

-

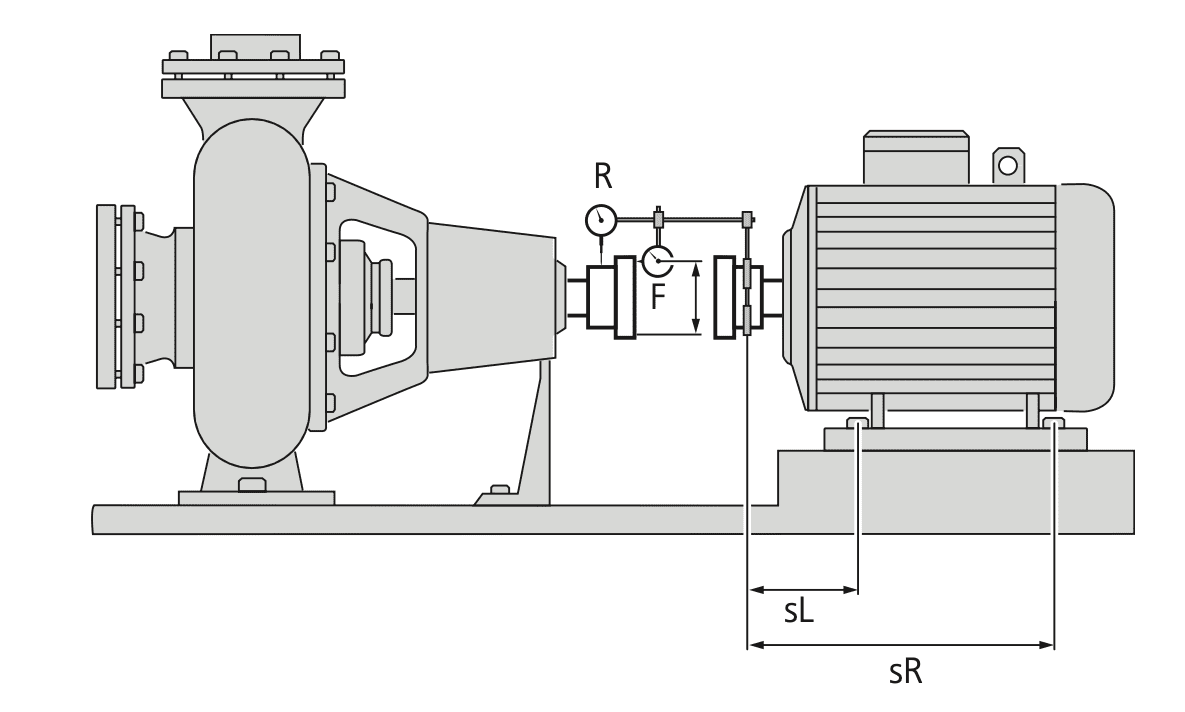

Initial Measurement: check the system geometry using dial indicators, micrometers, or laser alignment systems.

-

Static vs. Dynamic Alignment: static for installation, dynamic for machines operating under load or heat.

-

Tolerances: typically, offset and angular deviations must remain below 0.05 mm for industrial applications.

-

Scheduled Maintenance: include alignment checks in regular maintenance programs.

Modern Alignment Tools

-

Laser alignment systems ensure fast, precise, and repeatable measurements.

-

Integrated monitoring sensors continuously detect vibration or shaft displacement.

-

Thermal compensation tools correct for expansion and deformation during operation.

Installation Best Practices

-

Ensure flat, clean mounting surfaces.

-

Tighten bolts evenly to avoid distortion.

-

Check alignment after the first operating cycle.

-

Use proper lubricants suited to load and temperature.

-

Replace damaged or bent components immediately.

Benefits of Proper Shaft Alignment

-

Extended bearing life.

-

Reduced energy consumption.

-

Lower vibration and noise.

-

Increased equipment reliability.

-

Fewer unscheduled downtimes.

-

Lower total cost of ownership.

Conclusion

Shaft alignment is a critical factor for bearing reliability and mechanical efficiency.

Machines with correctly aligned shafts consume less energy, operate more quietly, and allow bearings to last up to three times longer than those in misaligned systems.

By integrating precise alignment procedures into your maintenance strategy, you ensure consistent performance, minimize wear, and extend equipment lifespan — a fundamental practice for every professional in industrial maintenance.