In the world of robotics and industrial automation, THK systems are among the most trusted solutions for designing automated machinery, collaborative robots and high-precision handling systems. With decades of experience

Guide to Maintenance of NSK Bearings

Maintenance of bearings is one of the most critical aspects for ensuring efficiency, longevity and safety in industrial machinery. Among the world’s leading manufacturers, NSK stands out for high quality,

NTN: How to Choose the Right Bearings for Your Machine

In the global field of precision mechanics, NTN is one of the most recognized and respected brands, known for its reliability, advanced technology, and high-quality bearings.Founded in Japan in 1918,

INA Roller Bearings: Innovation, Precision, and Reliability for Every Industrial Application

In the world of precision mechanical components, INA roller bearings stand out as some of the most reliable and high-performing solutions on the market.As part of the Schaeffler Group, INA

Timken Bearings: Quality and Reliability

In the industrial sector, choosing the right bearings is essential to ensure high performance, durability, and safety. Among the world leaders in bearing manufacturing, Timken has stood out for over

How to Prevent Bearing Contamination in High-Intensity Production Environments

In high-intensity production settings such as food processing plants, steel mills, chemical facilities, and automated assembly lines, bearings are subject to extreme operating conditions. Contamination from dust, liquids, metal particles,

Guide to CRAFT Ball Bearings: Reliability, Performance, and Versatility

When it comes to power transmission and industrial mechanics, choosing the right bearing can make all the difference. CRAFT ball bearings have established themselves as a solid and reliable solution,

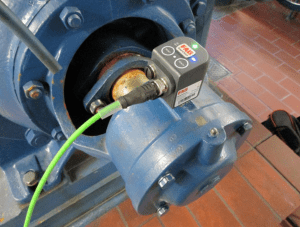

In the power transmission and rotating components sector, protection against contaminants is essential to ensure the operational longevity and efficiency of rolling bearings. SKF, a leading company in motion solutions

Bearings: The Importance of Preventive Inspections

As is well known, and as we have often reminded you on these pages, to allow bearings to maintain their performance as close as possible to the original efficiency for

Bearing Damage: What It Is and How to Identify It!

Bearings, when properly installed, lubricated, and kept clean, are designed to meet manufacturers’ performance objectives without significant issues. However, anomalies in manufacturing, assembly, or maintenance can sometimes cause premature damage,