As is well known, and as we have often reminded you on these pages, to allow bearings to maintain their performance as close as possible to the original efficiency for an extended period, it is essential to resolve and identify anomalies that could cause significant damage and failures in the future. Scheduled periodic maintenance and inspections are necessary to achieve this goal.

But what does this involve? And what precautions should be taken?

Operational Phase Inspections

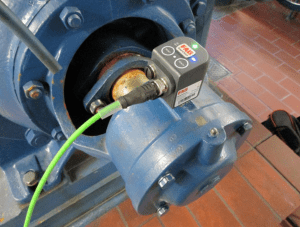

When it comes to preventive inspections, it is crucial to ensure proper monitoring of the bearing during its operational phase. Regular inspections should be carried out to detect noise levels during operation, monitor the temperature, or identify any vibrations. Even in cases of slight wear or flaking, irregular bearing noise can be promptly identified using a standard stethoscope.

As for temperature monitoring, while it is possible to detect obvious anomalies by simply touching the outer surface of the housing, for a more accurate check, it is advisable to measure the bearing’s temperature using a thermocouple inserted directly into the lubrication hole or a similar access point.

Inspecting “Difficult” Bearings

In some cases, bearings may be hard to access or not allow for “simple” checks like those described above. For example, this can apply to bearings mounted on moving parts, where it is not possible to measure noise or temperature during operation. Roller bearings in vehicles are a typical example, where periodic inspections can be carried out by applying fresh grease.

Examining the condition of fresh grease during bearing operation can also help assess the bearing’s operational state. This evaluation can be based on the level of contamination, the amount of metal shavings present in the grease, and any signs of leaks or grease deterioration.

As you might expect, if these checks reveal anomalies or signs of bearing failure, the bearing must be disassembled to conduct a more thorough inspection. This will help identify the root causes of the faults.

When Replacement is Needed

If the bearing needs to be replaced, we remind you that at Cuscinetti e Componenti, you will find the most extensive online catalog of bearings and other components from top brands for all types of machinery. With over 50,000 items, including industrial components, bearings, supports, oil seals, belts, linear guides, bushings, locknuts, washers, seals, idler pins, track rollers, support rollers, maintenance products, and much more, we have you covered.

Our customer support ensures the best pre- and post-sales assistance and is always ready to help you find personalized solutions.

Fast delivery throughout Italy, secure payments via credit card, PayPal, or bank transfer, and our “satisfied or refunded” guarantee are just some of the key benefits we are delighted to offer every day!